Description

Benefits of Bleeding Table

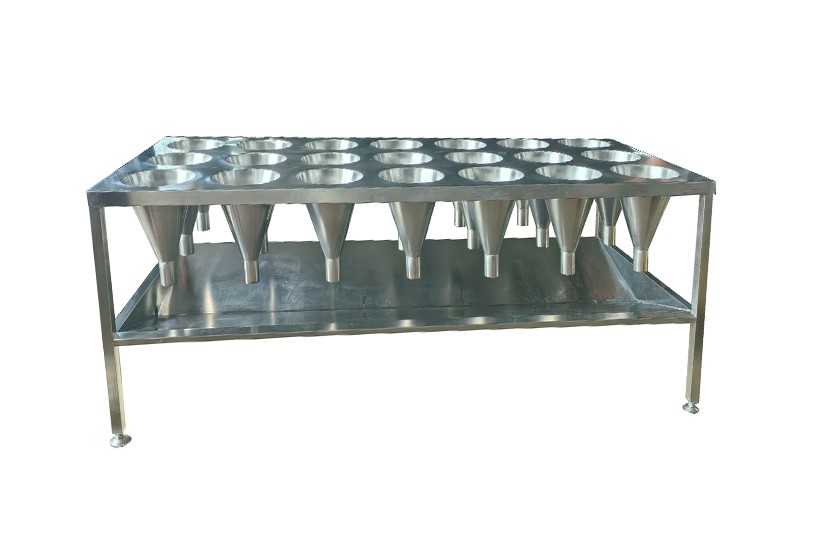

The 21-Cone Bleeding Table is made for slaughterhouses and poultry farms that require durability, hygienic conditions, and speed and it has a safe and user-friendly design, is constructed of 304 stainless steel, can process up to 300 birds per hour, and is simple to clean.

- Reduce labor and time by processing up to 300 birds per hour.

- Constructed with 304 stainless steel and which is sanitary and resistant to rust.

- With a slanted drainage system.

- Worker-friendly, featuring rounded edges and smooth surfaces.

- Investments that are future-proof help businesses expand.

- Sturdy welded frame designed for everyday and long-term use

Comparison: 10-Cone vs 15-Cone vs 21-Cone Poultry Bleeding Tables

| Feature | 10-Cone | 15-Cone | 21-Cone |

| Capacity | Small scale –up to 100 birds/hour | For beginners | Large scale –up to 300 birds/hour |

| Size | Compact, saves space | Moderate size | Largest, full processing line use |

| Best For | Small poultry farms | Medium farms and local processors | Commercial farms and slaughterhouses |

| Efficiency | Limited throughput | Balanced | Maximum throughput and reduces waiting time |

| Cleaning & Hygiene | Easy to clean | Easy to clean | Drainage system and faster cleaning |

| Worker Productivity | Slower | Slower and Medium | Fastest—more birds handled at once |

| Growth Potential | For beginners | For growing farms | Future-proof – supports expansion |

Reasons to Choose the 21-Cone Bleeding Table

In the above-mentioned, all the details are clear. The 21-cone table is best suited for poultry farms and slaughterhouses. It allows farms to process up to 300 birds per hour, saving time and it is made of 304 stainless steel and is stable and easy to use.

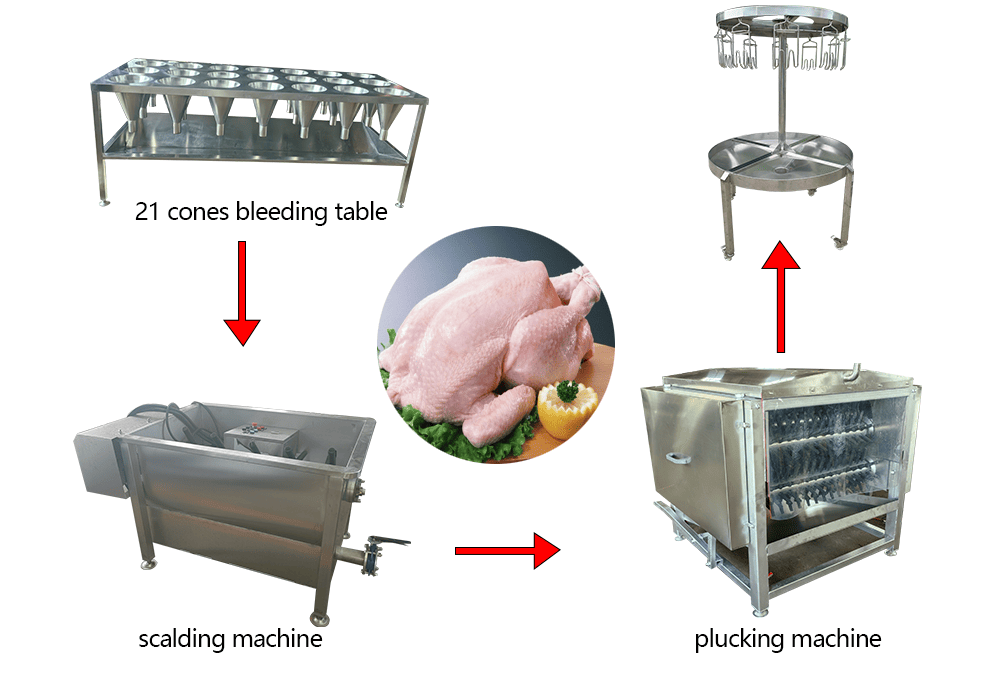

How to Use a Bleeding Poultry Table?

The bloodletting table is easy to use and effective.

- Place the bird into the stainless-steel cone, headfirst.

- To ensure the bird remains in place while bleeding, secure it.

- Cut in accordance with your processing needs.

- Permit blood to flow into the collection area via the sloping design.

- After the bleeding is finished, remove the bird and proceed to the following stage of processing.

- Rinse with hot water and sanitize after each use

Maintenance Guide of Chicken Bloodletting Tables

Hygiene and long-lasting functionality are ensured by maintaining the 21-cone bloodletting table clean.

- Rinse with hot water to get rid of any blood or residue.

- For proper cleaning and use food-grade sanitizer.

- To keep surfaces gleaming and prevent water stains/wipe dry.

- Regularly inspect cones and welds for durability and stability.

- When not in use, store in a dry and clean place.

FAQs

A 21-cone bleeding table is best for large farms and slaughtering plants since it will have a larger capacity and is designed to be used over a long period of time.

250–300 birds per hour may be handled by a 21-cone bloodletting table, although smaller ones (10- or 15-cone) handle fewer.

304 stainless steel provides safe meat processing and longer equipment life since it is rust-proof/hygienic and simple to clean.

To maintain cleanliness and prevent pollution and rinse with hot water/apply a food-grade sanitizer, and pat dry the surface.

Yes, stainless steel bleeding tables are versatile and well-suited to a range of poultry species and even though fit can be affected by cone size.

Ismail Pathan –

I bought this bleeding table it works great, easy and very helpful.

Liam –

Best quality product, makes Poultry bloodletting process quick and simple.

Henry –

Very useful table, easy to clean and handle, worth the money.

Adil Khan –

Perfect for bulk chicken processing, best build quality and easy maintenance.