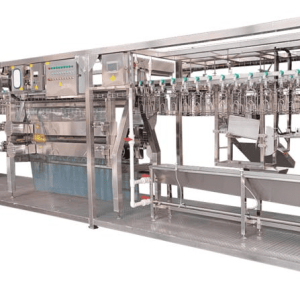

Poultry slaughtering equipment which might be speedy and secure for farms. The poultry slaughtering system allows the processing of birds faster and more efficiently. It takes care of each step appropriately and reliably. From small farms to large fields, these slaughter equipment save time, make work easier, and hold the meat sparkling.

As we are manufacturer of farm poultry equipment so we offer whole solutions for all types of slaughterhouse equipment line. Our machines are manufactured from strong stainless steel and meet strict food protection regulations.

What is Poultry Slaughtering Equipment?

This is a group of machines used to process chickens and other birds for meat, which makes the work faster and safer than by hand. They help to prepare and handle birds with cleanliness, and this equipment is mostly used in farms and meat plants to save time, reduce hard work, and give better quality meat.

Benefits of Using Our Slaughter Machine Line

Right equipment means faster work, cleaner results, and less effort. Below are the key benefits you get from using our poultry slaughtering equipment:

- Faster processing with less manual work.

- Uniform quality across all processed birds.

- Hygienic design for safe food production.

- Reduced labor costs and higher output.

- Flexible setups that can grow with demand.

Modern slaughterhouse machines are essential for both medium farms and large plants.

How to Use Our Poultry Slaughtering Equipment

Operating furuida’s manufactured slaughterhouse machine line is simple when staff are trained. The process usually includes-

Stunning and Bleeding

The first step is to make the birds unconscious so they do not feel pain. This is called stunning and can be done using electricity or gas. After stunning, the birds are bled by cutting the main blood vessels. This is important to keep the meat clean and safe.

Scalding and Plucking

Next, the birds go into the scalding machine. He loosens the heat wings so that they descend easily. The birds are then put into a plucking machine with soft rubber fingers that pull the wings.

Evisceration and Washing

In this step, remove the internal organs by using an eviscerate table, open the body’s cavity and remove the intestines and other parts. After that, wash birds with clean water to remove blood, dirt, and any remaining wings.

Chilling

Once the birds are cleaned, they cool quickly in cold water or an air chiller, and this step cools the meat, prevents germs from growing, and keeps it fresh.

Packing

Finally, the birds are weighed, sorted, and packed in clean packaging. They are then stored in cold rooms or sent out for delivery, ready for sale.

Maintenance Guide of Slaughterhouse Machine

To keep your poultry slaughtering equipment working well for a long time, regular care and proper maintenance are important. Below are some simple tips to follow:

- Wash and sanitize after use.

- Oil moving parts when needed.

- Replace worn parts quickly.

- Follow the service schedules from the maker.

- Train staff on correct machine handling.

Proper care makes the machines last longer and keeps your slaughterhouse equipment line running well.

Why Choose Us for Slaughter Equipment?

We focus on providing strong, reliable, and cost-effective poultry slaughtering equipment that makes poultry processing easier and more efficient. Below are the key reasons why our machines stand out:

- Made from high-grade stainless steel.

- Built to meet global food safety rules.

- Custom-made to fit your capacity.

- Supported by expert installation and after-sales service.

When you work with Furuidaequipment, you get a trusted partner in poultry processing.