10 Must Have Meat Processing Equipment for Efficient Production

Efficiency, consistency, and quality are important in the competitive meat industry. The right equipment is the key to an efficient meat processing plant. Selecting the right tools not only enhances productivity but also promotes food safety and reduces waste.

In this blog, you’ll get to know about the 10 must have meat processing equipment that every production facility should use. These essential tools help improve efficiency, maintain quality, and speed up overall meat processing.

What is Meat Processing Equipment?

Meat processing equipment refers to machines and tools used to handle, process, and prepare meat for consumption or sale.This machinery has a coverage of all production stages including initial cutting and grinding, blending, tenderizing, packaging and storage. These machines aim to enhance efficiency, maintain product consistency, ensure hygiene, and reduce waste.

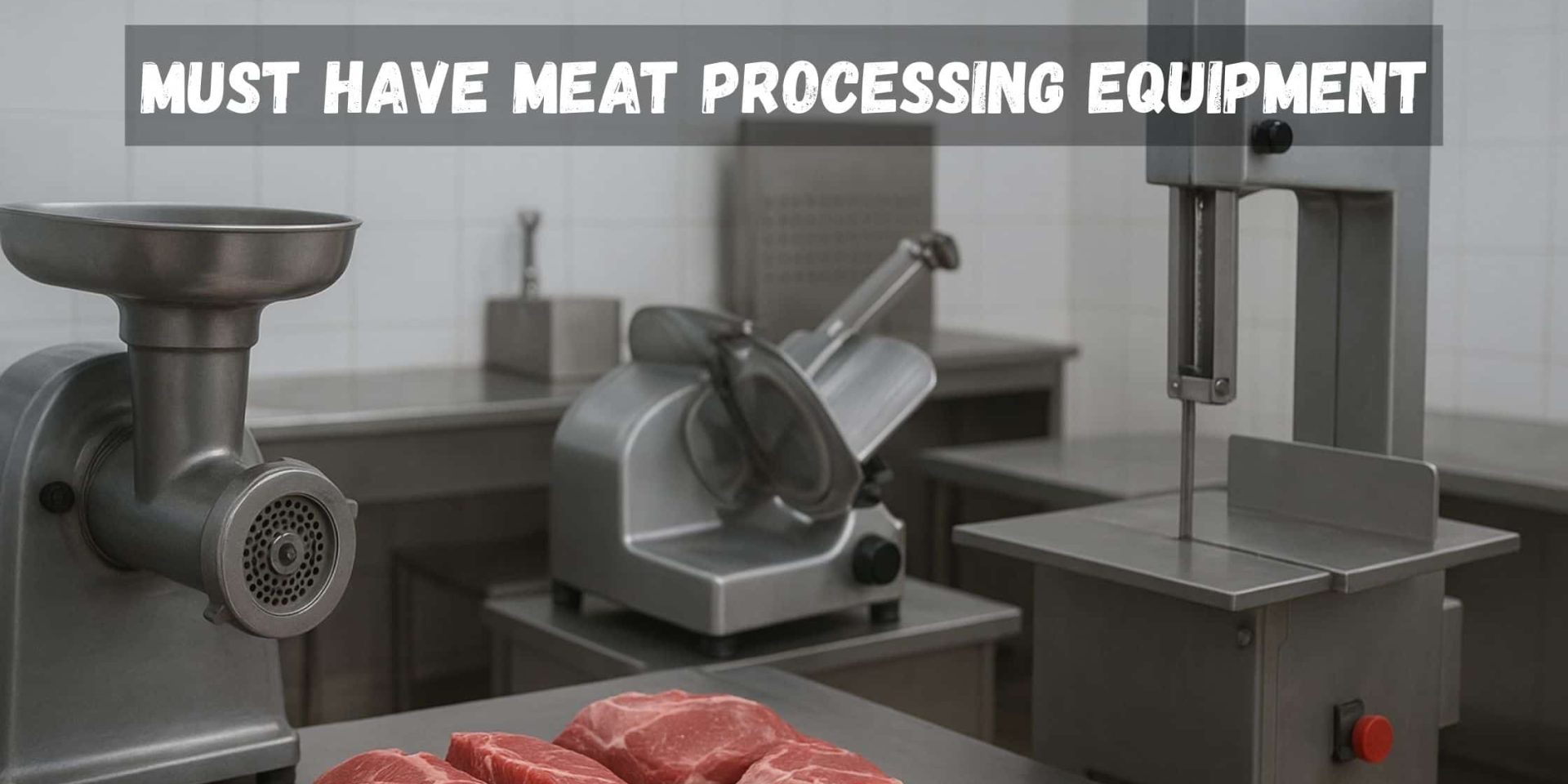

These are meat grinders, slicers, sausage stuffers, mixers, bandsaws, packaging machines and refrigeration units. Operating on the appropriate equipment enables the meat processing facilities to operate safely, to meet industry standards, and to provide superior quality products to the consumers.

Must Have Meat Processing Equipment

Meat Grinder

A meat grinder is a necessary tool to make regular minced meat. Whether grilling burgers, sausages, or other meat products, it ensures consistency in texture and size. It is time saving in processing and it is flexible to process other types of meat. For quality and efficiency, using an industrial meat grinder for commercial processing is highly recommended.

Meat Slicer

Meat slicers ensure meat is cut into precise, even slices for sale or packaging. These machines may also be adjusted to different thicknesses, safety features to avoid accidents, as well as high speed, which is beneficial in large batch handling. Meat slicers make the work more efficient and preserve the quality of products.

Sausage Stuffer / Filler

A sausage stuffer is necessary in the production of sausage. Automatic fillers also enhance the speed of production, consistency in sausage size and help meet hygiene requirements. They are more consistent and save labour as compared to the manual models. Sausage stuffer machine and automated meat filler are some of the popular keywords used to refer to this equipment.

Vacuum Tumbler / Meat Mixer

Meat kept in vacuum tumblers or meat mixers is rapidly marinated and tenderized. They aid in even distribution of marinades, improve meat tenderness, and reduce processing time, leading to better product quality.

Meat Cutter / Bandsaw

The large blocks of meat are cut into smaller portions using the help of a meat cutting machine or bandsaws. They are precise machines that are fast and accurate, with safety features to protect operators. They are perfect in processing high amounts of meat in an effective manner.

Meat Tenderizer

Tenderization of meat enhances the meat and makes it more palatable. Mechanical types of tenderizers such as blade or needle types are commonly used in commercial operations. Manual tenderizers can also work well in the case of smaller operations.

Mixer Grinder / Meat Blending Machine

In terms of such products as sausages or patties, it is important that they be blended regularly. Mixer grinders ensure spices and meat are evenly blended, maintaining consistent flavor and texture in every work. They save time and improve the product’s quality.

Packaging Machine

Meat should be well packed to preserve it, extend shelf life, and be hygienic. Alternatively, vacuum packing, flow wrapping, and skin packaging are available, each suited to different products. The presentation and branding is also improved and the chances of contamination are minimized through packaging machines.

Refrigeration / Cold Storage Units

Cold storage plays a very important role in ensuring quality and safety of meat. Processing plants involve the use of walk-in cold rooms, blast chillers, and display freezers to preserve and distribute meat without contamination.

Cleaning & Sanitation Equipment

Hygiene in processing meat is a matter of no compromise. Proper drains, washing equipment (high pressure washers) and sanitizers are used to prevent contamination and comply with food safety regulations. Cleaning and sanitation equipment enhances efficiency in operations and ensures that the production environment is safe.

Conclusion

The appropriate chicken processing equipment is necessary to enhance efficiency, quality of products, and profitability. Ginders and slicers, packaging machines, and cold storage, each of these operations is important for streamlining production and minimizing waste.

With the selection of the trustworthy solutions at Furuida Equipment, the meat processing plants will be able to use long-lasting and high-performance equipment that will help to get smoother production flow and improve hygiene standards. An upgrade to include these key tools is a smart move toward optimizing productivity and competitiveness in the industry.

FAQs

Q1. What is meat processing equipment?

A. Meat processing equipment includes machines used to cut, grind, mix, tenderize, package, and store meat.

Q2. Why is it important?

A. It makes meat processing faster, keeps the quality consistent, and helps maintain hygiene and safety.

Q3. What are the main types of meat processing equipment?

A. Common machines include grinders, slicers, sausage stuffers, mixers, cutters, packaging machines, and refrigeration units.

Q4. Can small businesses use meat processing equipment?

A. Yes, there are small-scale machines for butcher shops and large-scale machines for factories.

Q5. How do I keep meat processing machines safe and clean?

A. Always follow the manufacturer’s instructions, clean machines regularly, and use equipment with safety features to prevent accidents.